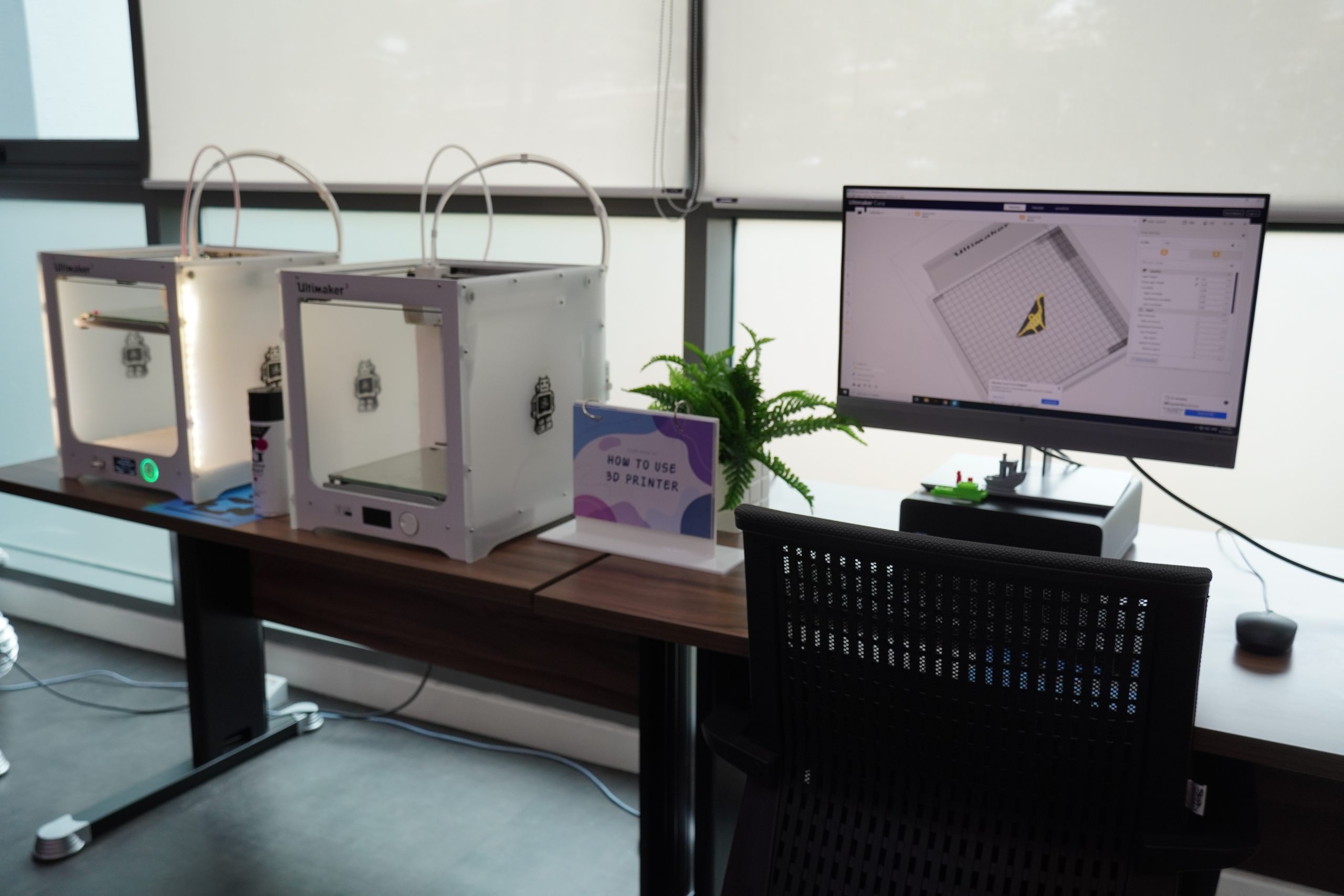

A place where all makers and thinkers (like yourself) come together to collaborate and create innovative solutions from an idea. Explore your very own interests and develop your projects today.

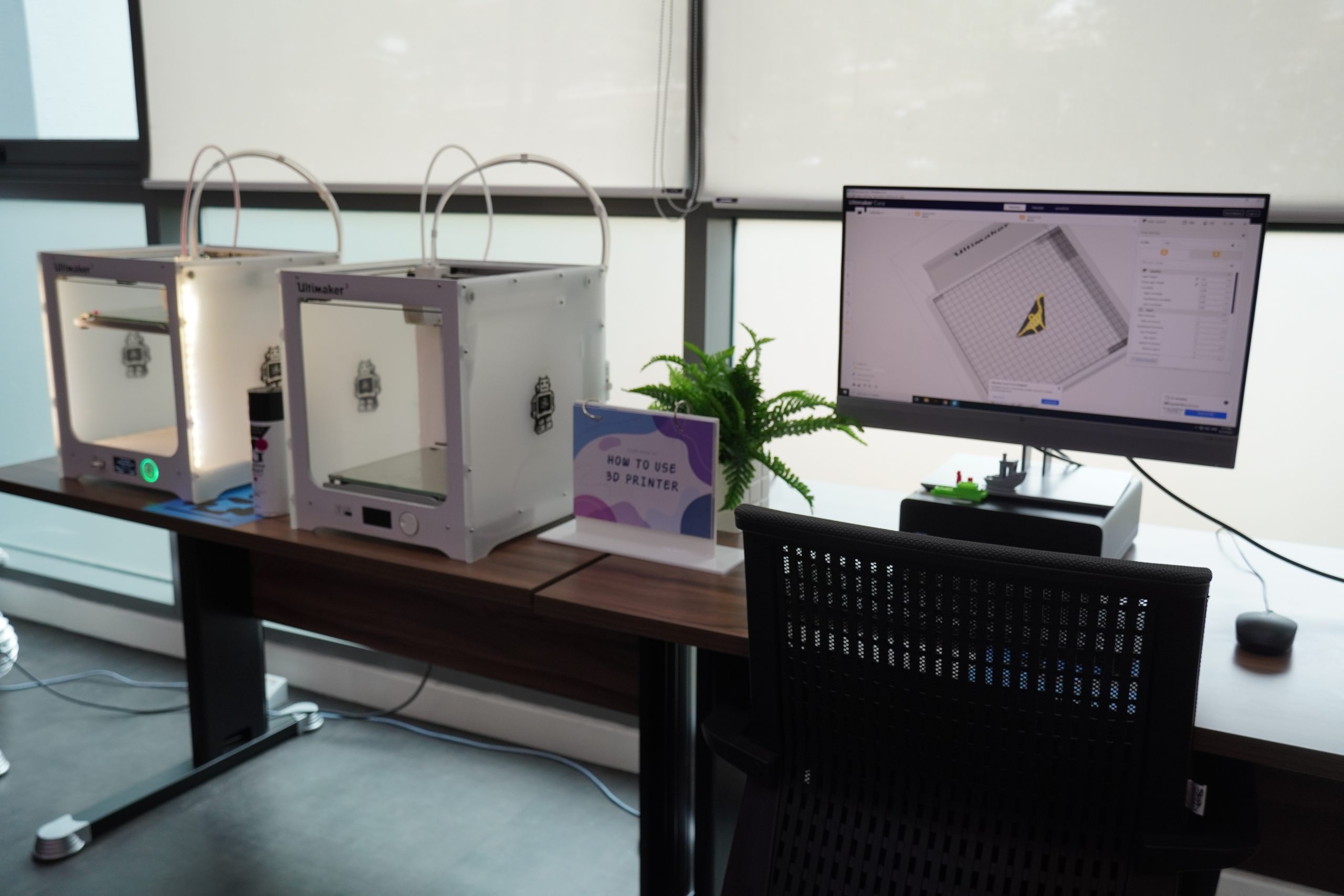

A place where all makers and thinkers (like yourself) come together to collaborate and create innovative solutions from an idea. Explore your very own interests and develop your projects today.

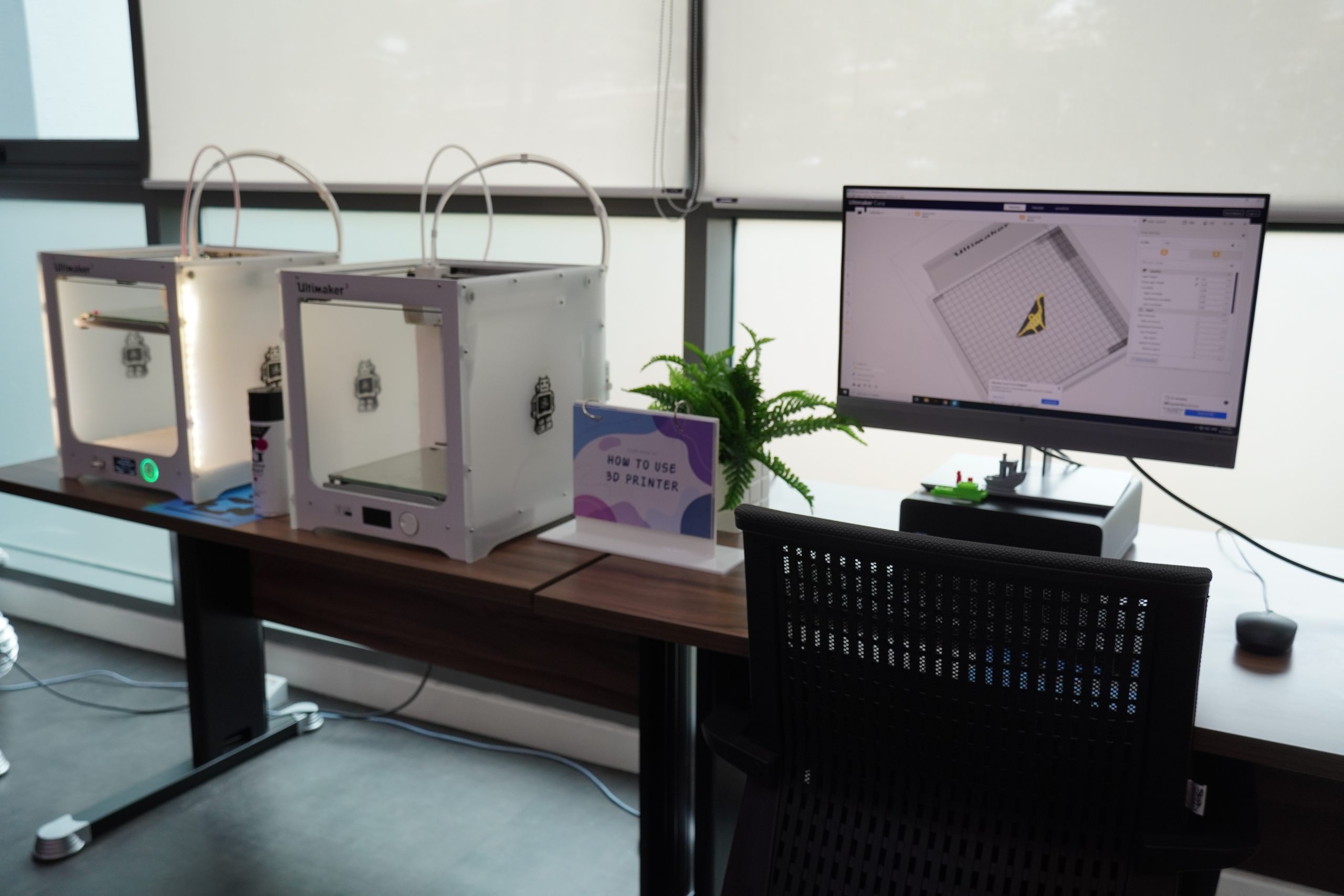

A place where all makers and thinkers (like yourself) come together to collaborate and create innovative solutions from an idea. Explore your very own interests and develop your projects today.

Our facilities and tools are free for all Sunway University students and staff.

Our facilities and tools are free for all Sunway University

students and staff.

Our facilities and tools are free for all Sunway University students and staff.

A community for students who learn best by doing. It does not matter if you’re a freshman or an experienced maker, everyone learns together in a conducive and supportive environment. Be part of the community today.

A community for students who learn best by doing. It does not matter if you’re a freshman or an experienced maker, everyone learns together in a conducive and supportive environment. Be part of the community today.

A community for students who learn best by doing. It does not matter if you’re a freshman or an experienced maker, everyone learns together in a conducive and supportive environment. Be part of the community today.

(Beside the lifts of the library)

(Beside the lifts of the library)

Sunway Innovations Labs (1420603-K)

Sunway FutureX,

Duplex, Jalan PJS 11/26,

Bandar Sunway,

47500 Subang Jaya, Selangor